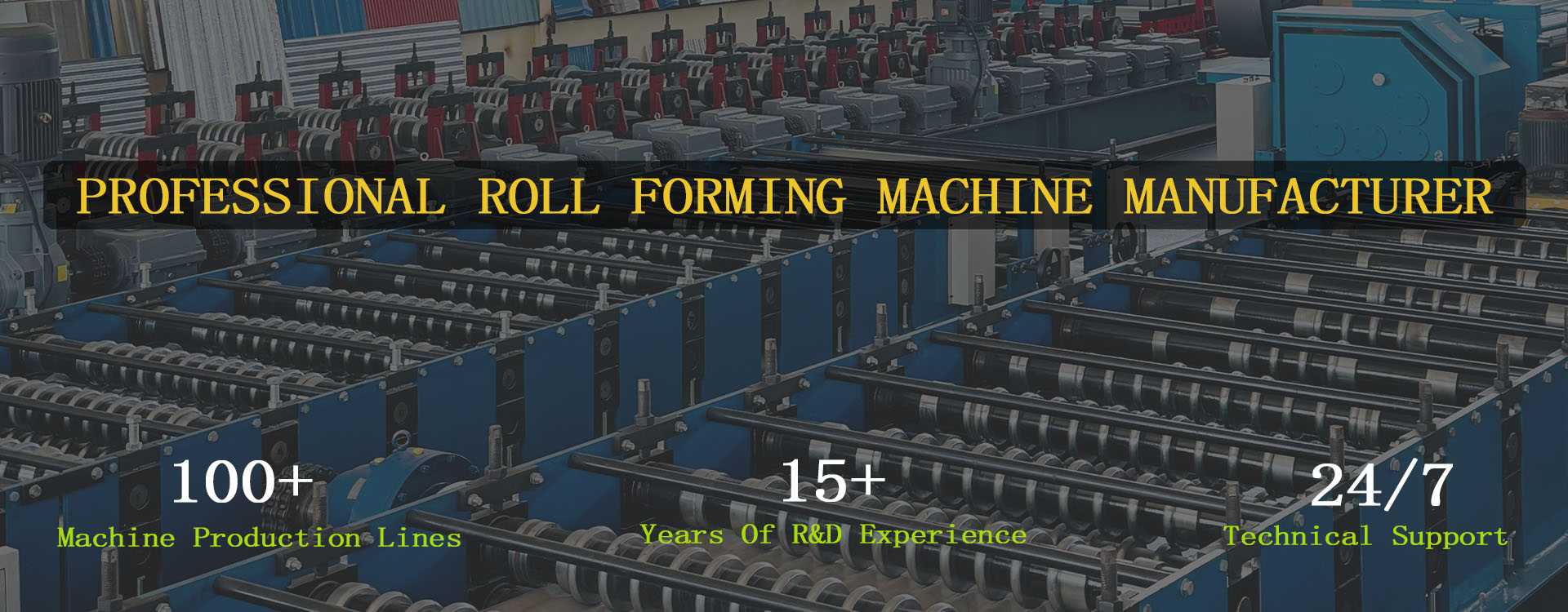

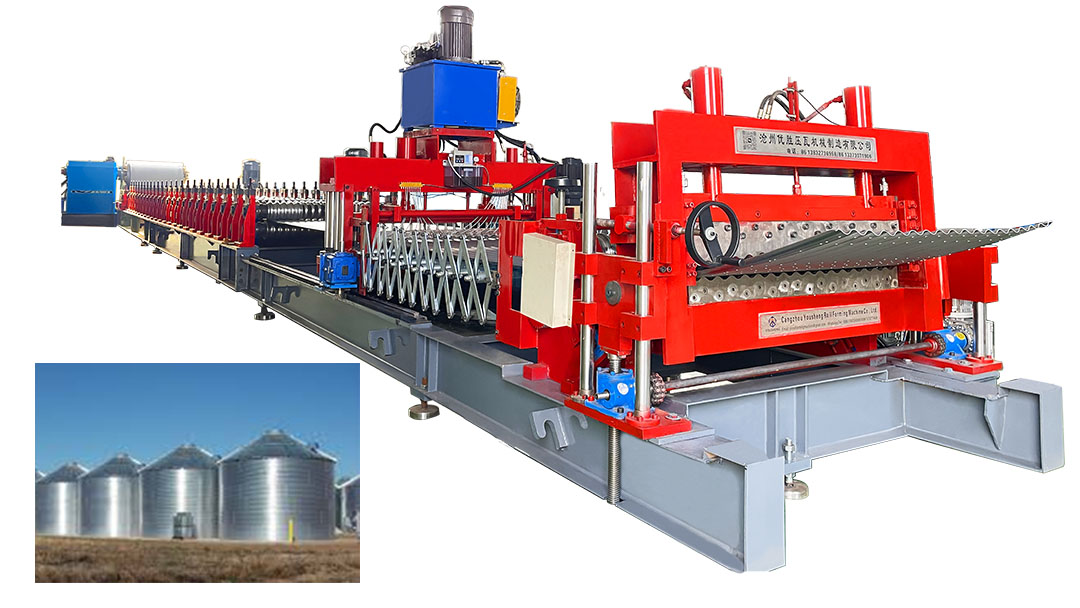

One-Stop Roll Forming Machine Solution

Hot-selling Products

Material: G550/High-Strength Steel

Thickness: 0.1-0.5mm

Production: 2-6 tons/day

Applicable Material: Galvanized

Processing Thickness: 0.5-4.0mm

Customizable

Materials: PPGI/Aluminum/Stainless Steel

Processing Thickness: 0.3-0.7mm

Forming Speed: 15-20m/min

Applicable Material: GI

Processing Thickness: 0.3-1.0mm

Forming Speed: 25m/min

Applicable Material: Galvanized Steel Coil

Processing Thickness: 1.5-3.2mm

Speed: 25 m/min (including punching)

Applicable Material: Galvanized steel coil

Thickness: 0.6-1.2mm

Customizable patterns

Why Choose Us

We produce machines according to customer requirements, meet customers’ various size requirements, provide customers with customized products, debug the machines before leaving the factory, and process precise size materials for customers.

High rigidity and stability are the basis for ensuring processing accuracy. The large frame structure has a stronger ability to resist and pull the workpiece deformation due to gravity, thereby maintaining higher geometric accuracy and positioning accuracy in long-term use.

Our Services

-

-

Customized roller forming machine design

-

Installation, commissioning, and pilot production support

-

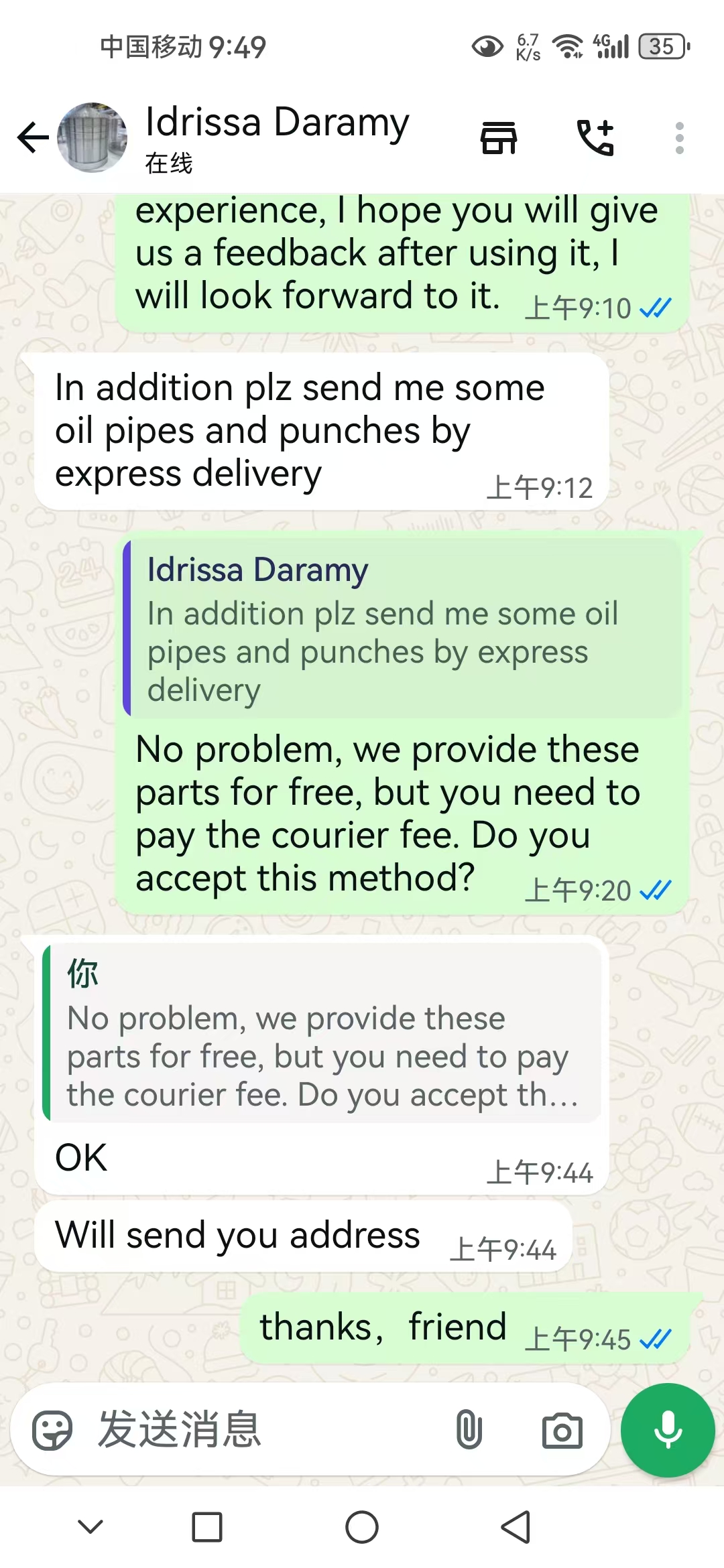

Strong technical support and remote diagnostics

-

Equipment upgrade and retrofit services available

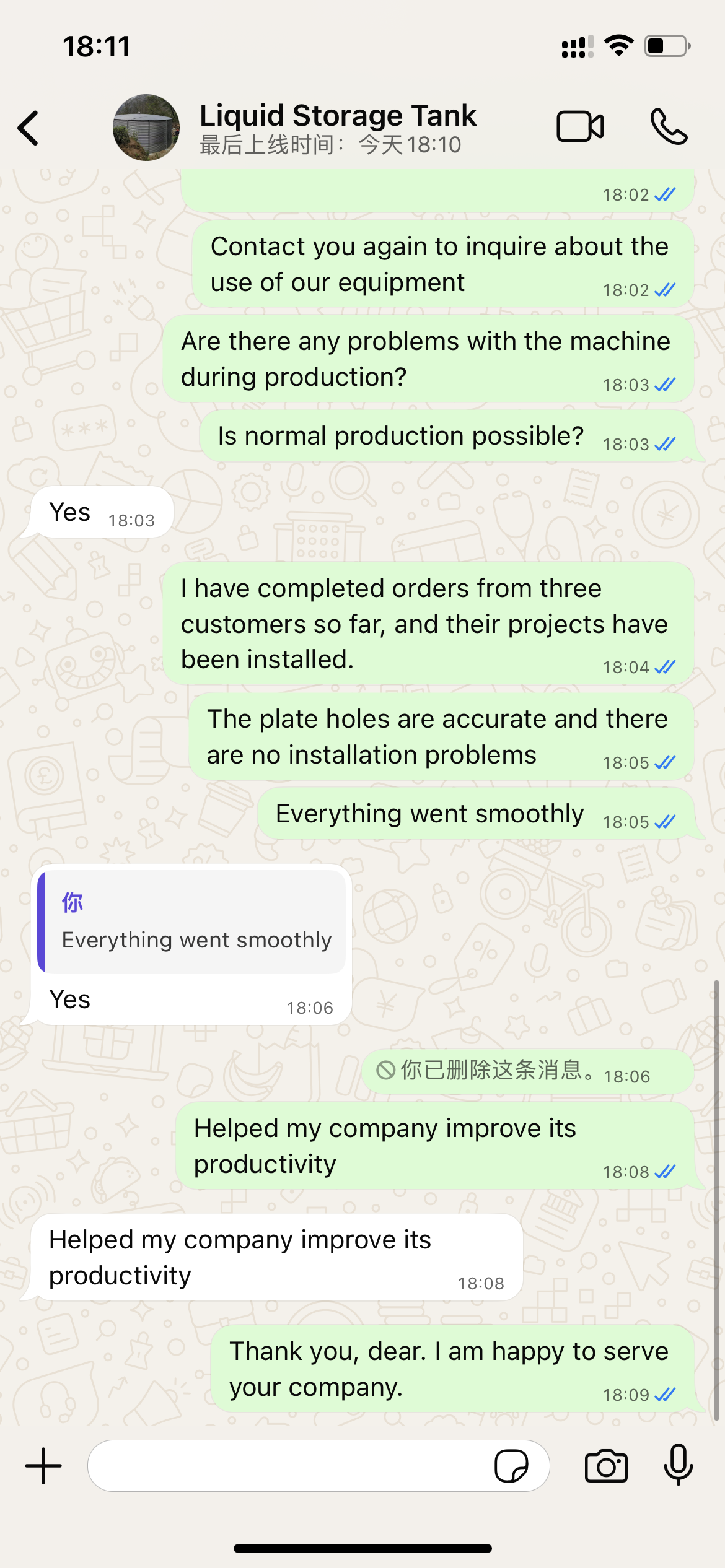

Of course. We have machine operation videos, and if conditions permit, we can arrange a live video demonstration or even arrange a factory visit for customers in your area.

Yes. We offer on-site installation and training if needed. For remote customers, we offer video instructions, 3D machine manuals, and online support via Zoom or WhatsApp.

We provide a one-year warranty on the entire machine (including wearing parts). We also provide lifetime support and spare parts supply.

Contact Now

Hello! My company is in need of a silo forming machine to meet our grain storage needs. Could you provide a product catalog?

I look forward to hearing from you!