Cold forming machines for various industries

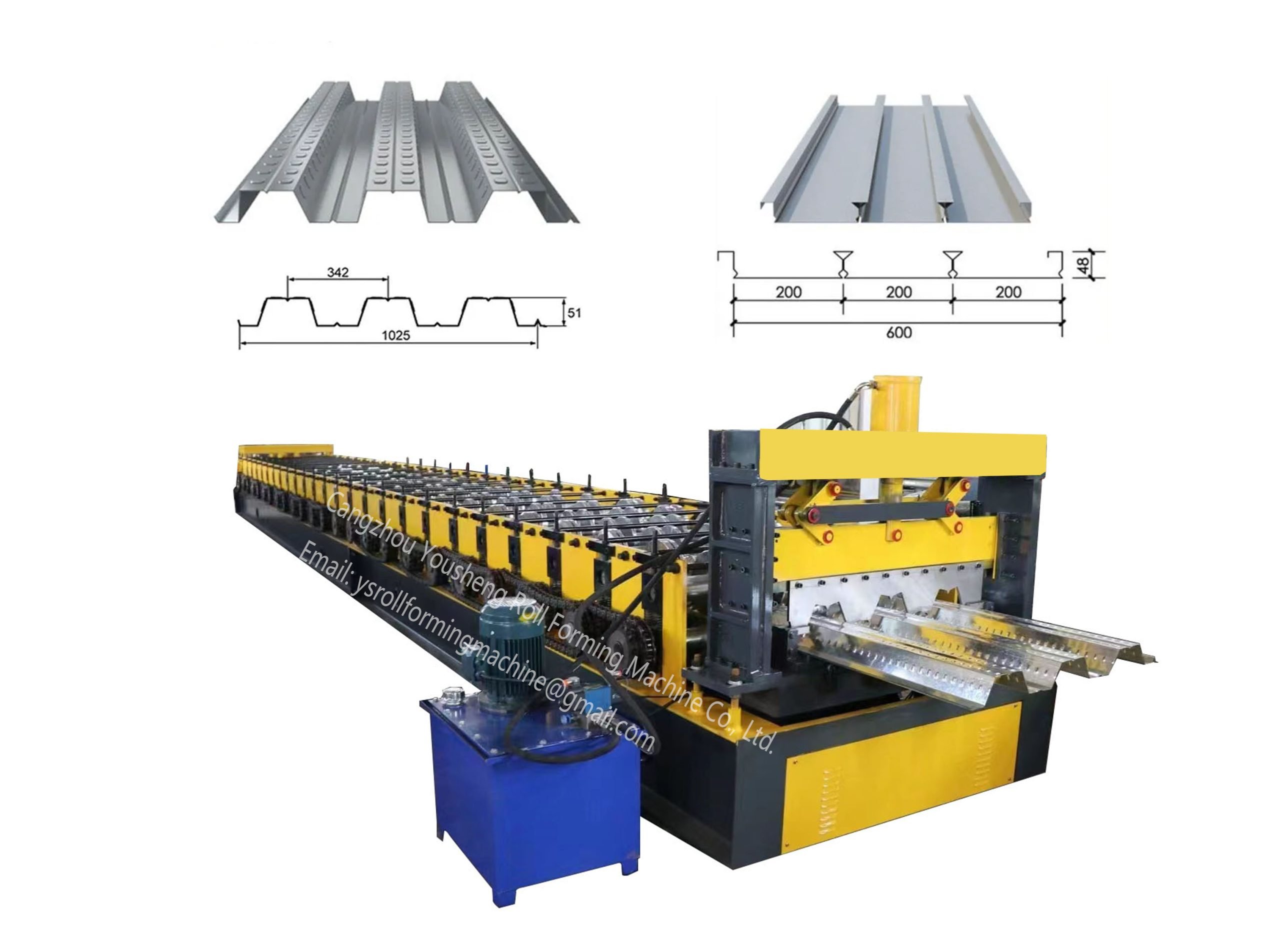

- Floor Deck Forming Roll Machine

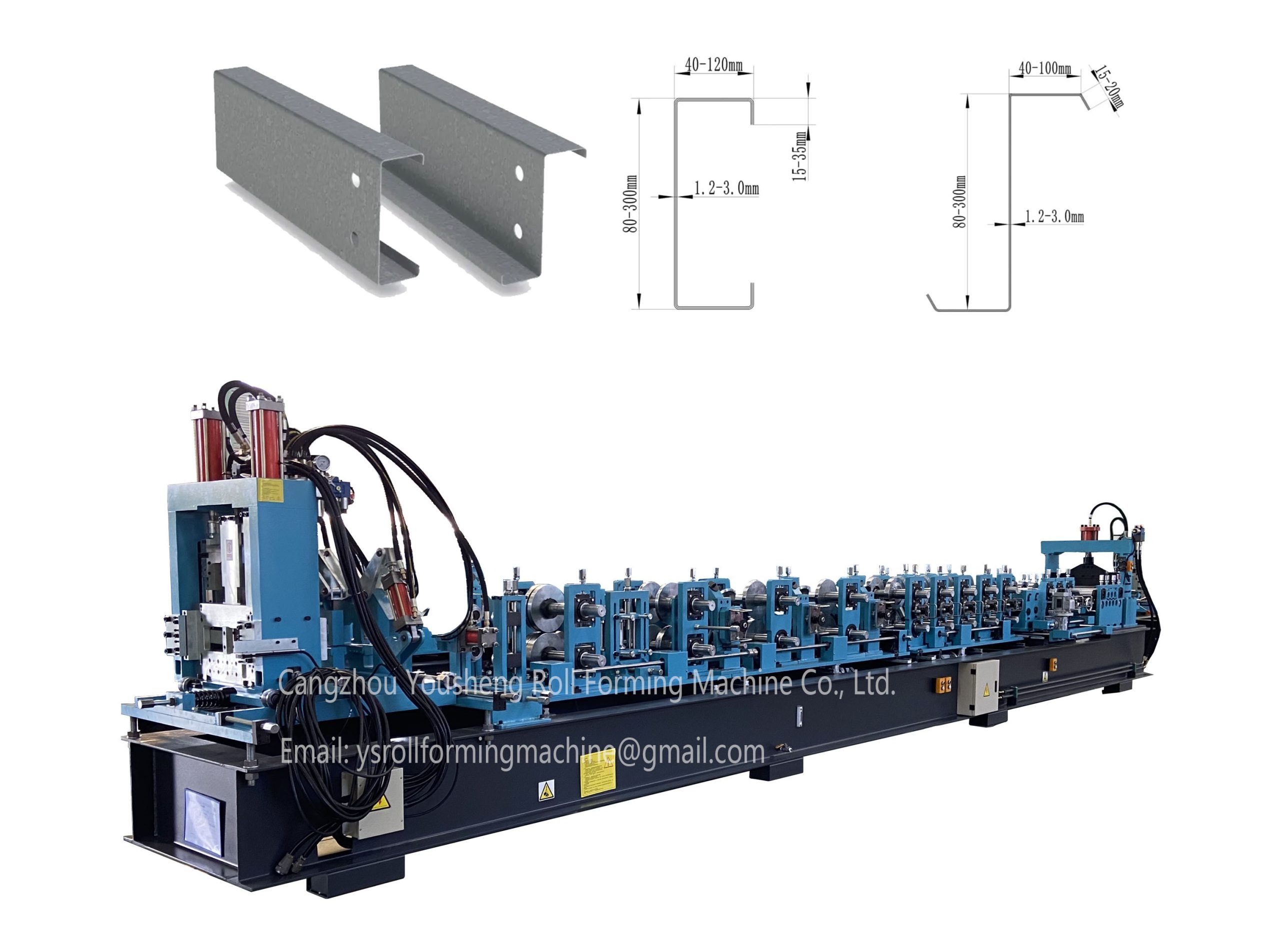

- Automatic CZ Purlin Forming Roll Machine

- Storage Steel Silo Forming Roll Forming Machine

- Metal Roof Sheet Forming Roll Machine

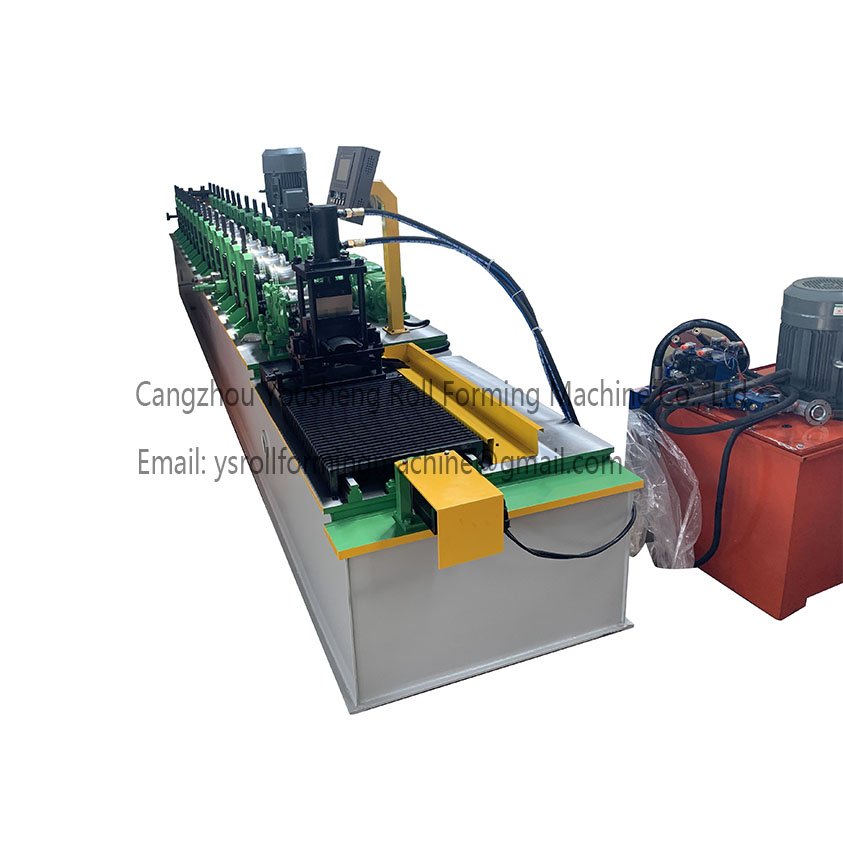

- Drywall Stud And Track Roll Forming Machine

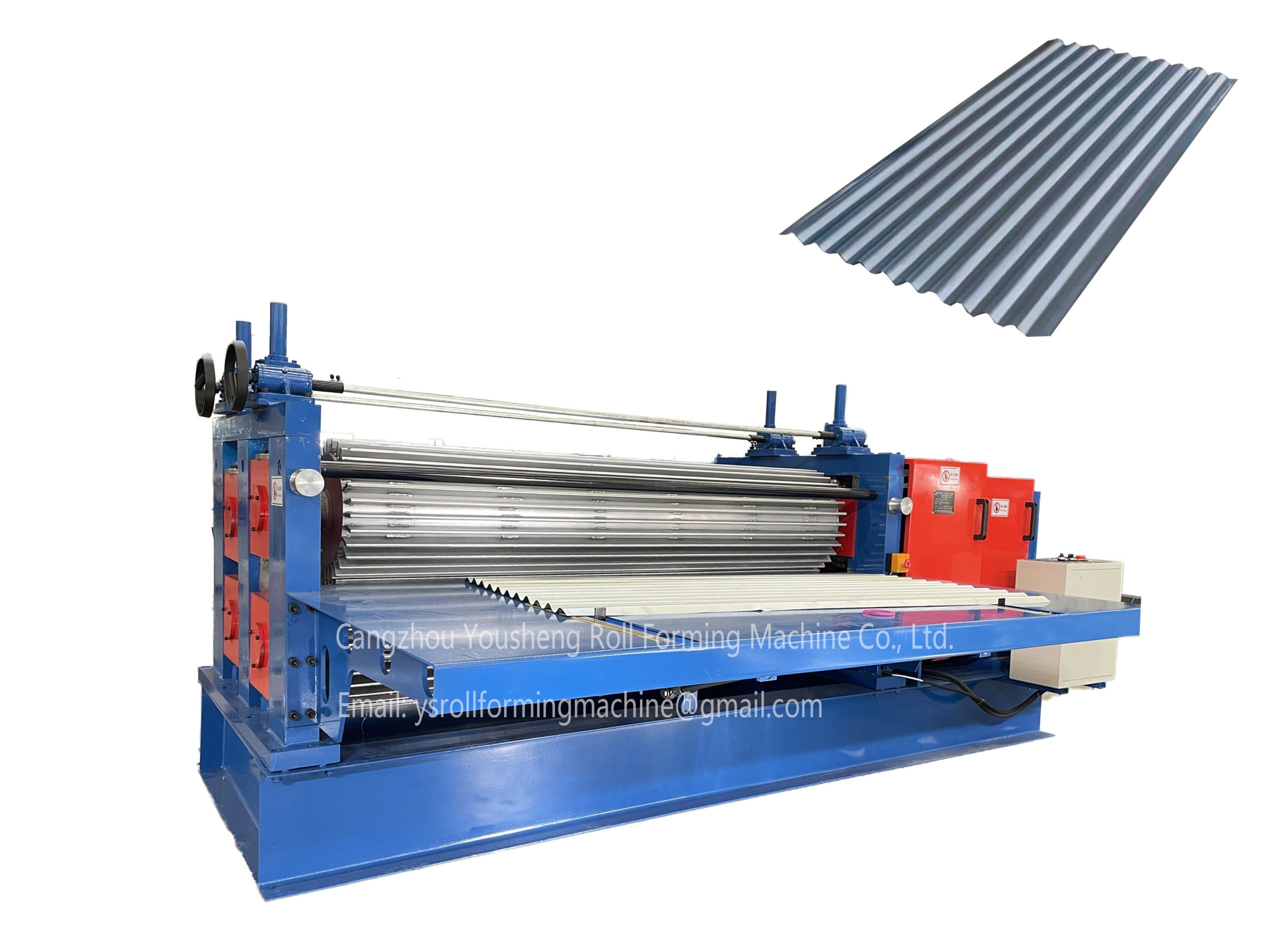

- Barrel Corrugated Roll Forming Machine

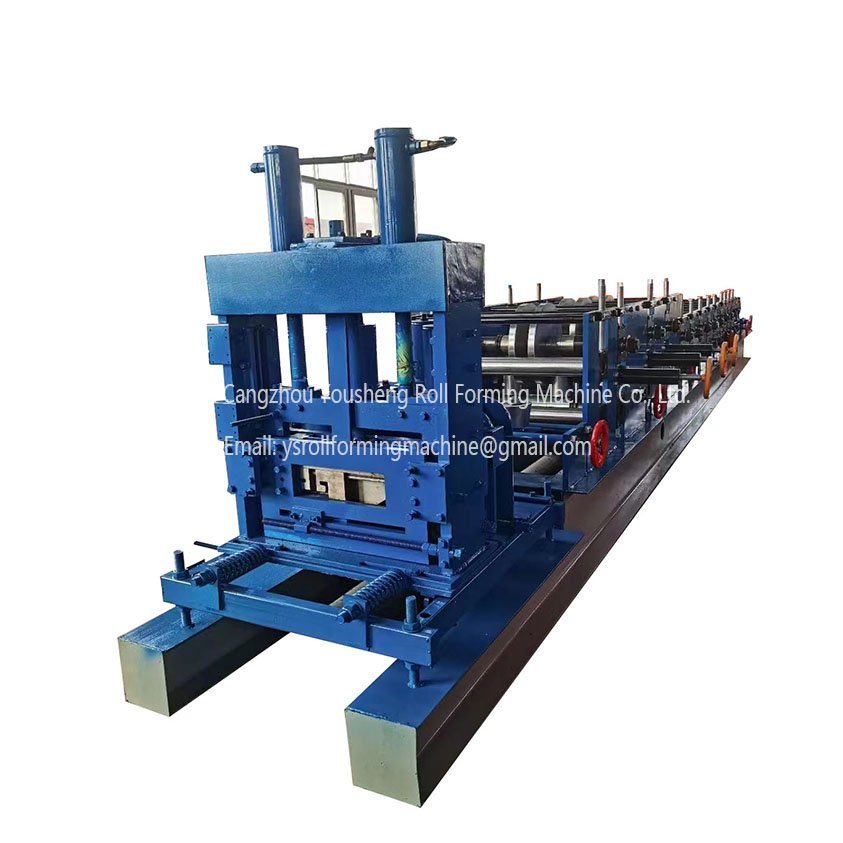

What is Roll Froming Machine

The cold-formed tile press is composed of a large frame base, a mechanical transmission, a hydraulic forming and cutting system, an electrical control system, and an auxiliary system. When working, place the bracket of the auxiliary system in the color steel sheet for cold-rolled tile processing between the cold-rolled tile rollers, start the power system so that the motor drives the sprocket, and the sprocket drives the roller to perform cold-pressed color. The steel plate is rotated by several cold-bending rollers and relies on friction to drive the raw material to move forward steadily and slowly, and at the same time, it is gradually pressed to form the arc required by the design, so as to realize continuous cold-bending operation. At the end of the cold-bending tile pressing, it enters the cutting system at the same time, and the computer control system is used to form and cut according to the parameter requirements, and then the color steel plates that have completed the cold-bending tile pressing work will be collected in the receiving rack to complete all the tile pressing processes

Forming Machine

We customize models according to customer requirements and provide one-stop service.

The double-layer roof panel machine can process two different versions, which can save the customer’s floor space, and the double-layer machine is also the most popular model among customers.

Australian-style rolling shutter doors are widely used in general stores, stores, shopping malls, schools, annexes, factories, stations, banks and factory buildings, and can be customized according to customer size.

Floor deck profiles can be seen everywhere in large-scale construction sites. The machine can roll ordinary raw materials to a thickness of 0.75-1.2mm, and other thicknesses can be customized.

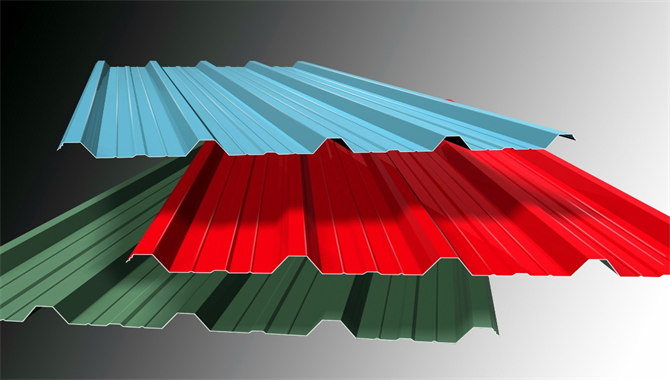

The tile forming machine is a machine composed of discharging, forming, and cutting after forming. The appearance of its color board is smooth and beautiful, the paint pattern is uniform, the strength is high, and it is durable.

Our company’s hydraulic uncoilers include 5 tons, 10 tons, 15 tons, 20 tons, etc. The uncoilers with trolleys are more labor-saving and can realize real full automation to satisfy every customer.

The roll forming machine developed by Yousheng Machinery is suitable for producing corrugated profiles. The machine can roll 0.1-0.5mm G550 galvanized coils, and the produced plates can be used for the construction of wall panels.

Product By Customized

All of our machines are customized for each customer

Product By Another Feature Like Size etc

Advantage

Custom Design Any Profile For Your Business

You can choose to customize your version, we can produce it in various thicknesses, various shapes and various materials. If you have special needs, please contact us.

Application Fields And Installation Of Roof Panels

Roof panels are mostly used in construction and project construction industries, and can be seen everywhere in large factories, residential houses, etc.

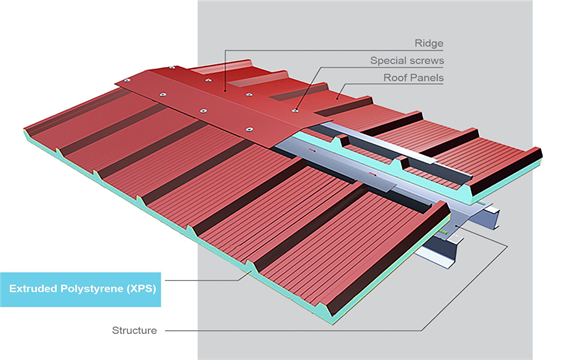

In the use and installation of house panels, our engineers have many years of experience and mature technology. House panels are divided into horizontal lap and vertical lap, and house panels.Roof panels are mostly used in construction and project construction industries, and can be seen everywhere in large factories, residential houses, etc.

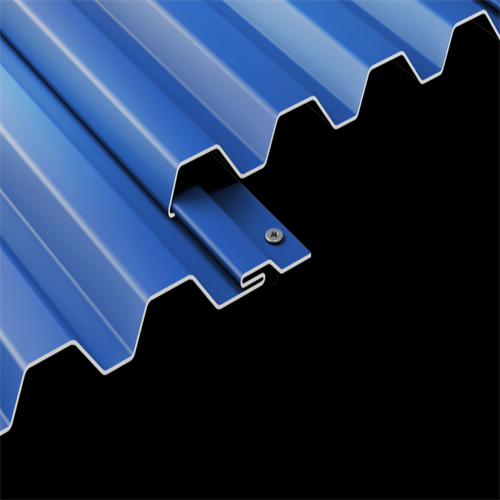

How to lap and install the roof panels?

There are four seam construction methods for the edge of the pressure plate, namely the natural lap method, the waterproof cavity method, the buckle cover method and the seam curl method

The installation of the roof panel should be smooth and smooth, the outline of the flashing and wrapping should be straight, and the sealant should be applied to the overlapping joints

About YOU SHENG

We were established in 2004. The boss was engaged in the processing of rollers. Until 2009, we established a physical factory of cold-bending machines, which were sold to many regions in China. We have our old customers. We adhere to high-quality and good services to win customers

We have our own processing workshop, production workshop and assembly workshop, from the processing of parts to the assembly of machines, all are completed in the factory

We are composed of production team, after-sales team, sales team, design team and inspection team