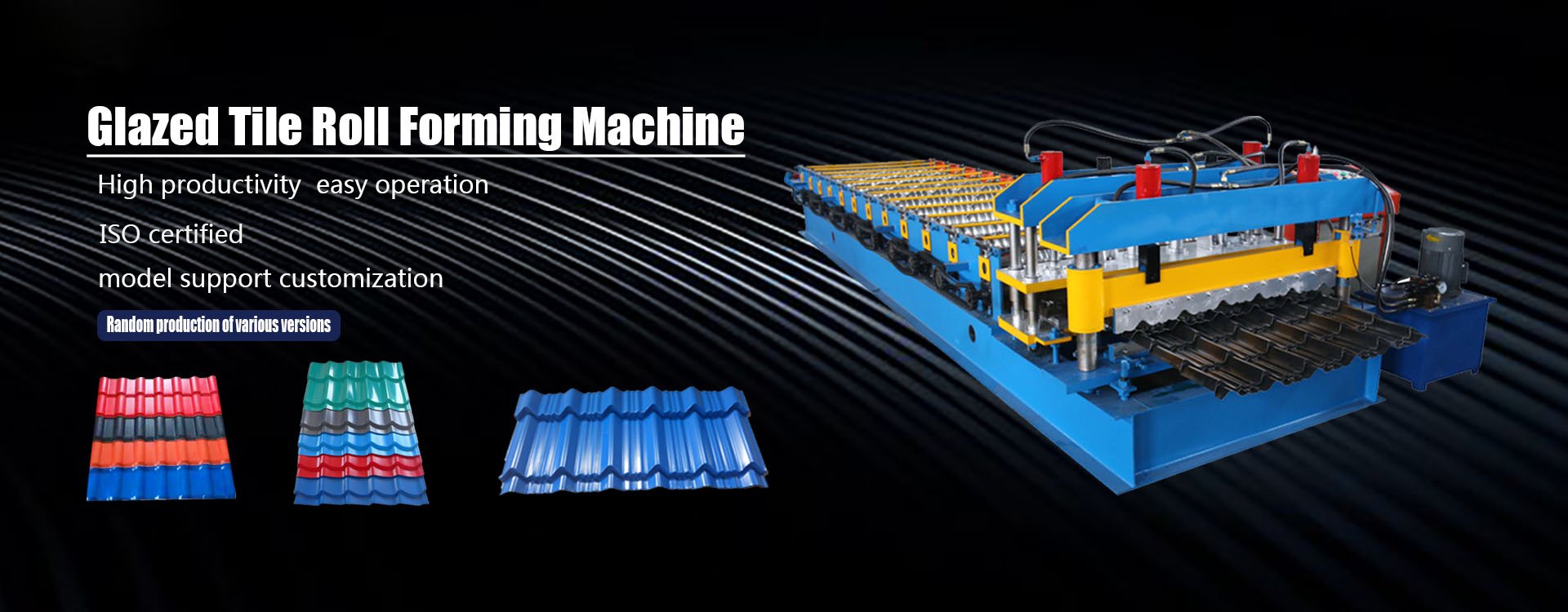

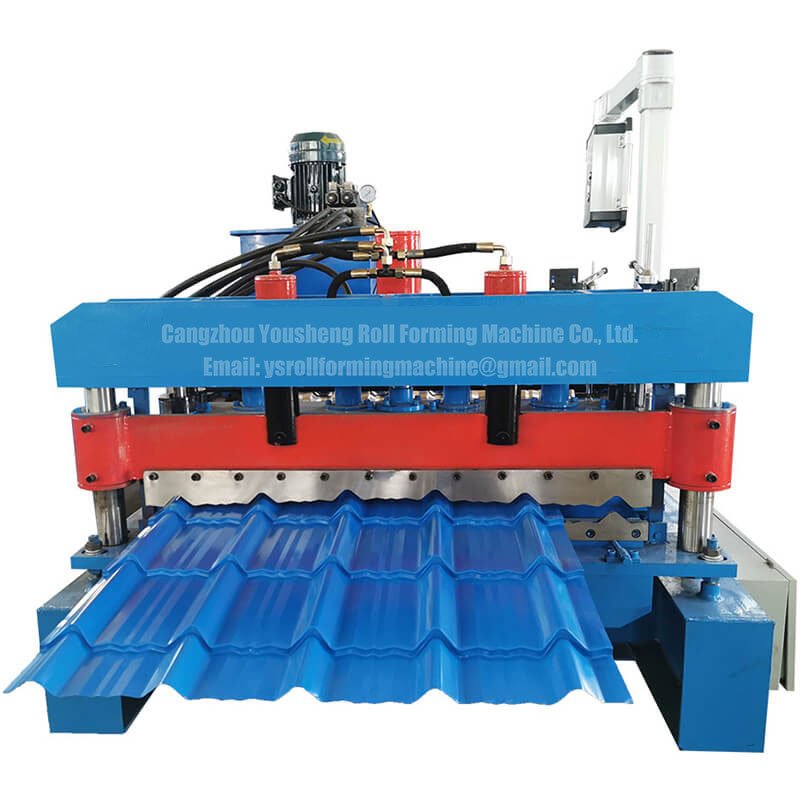

Glazed Tile Roll Forming Machine

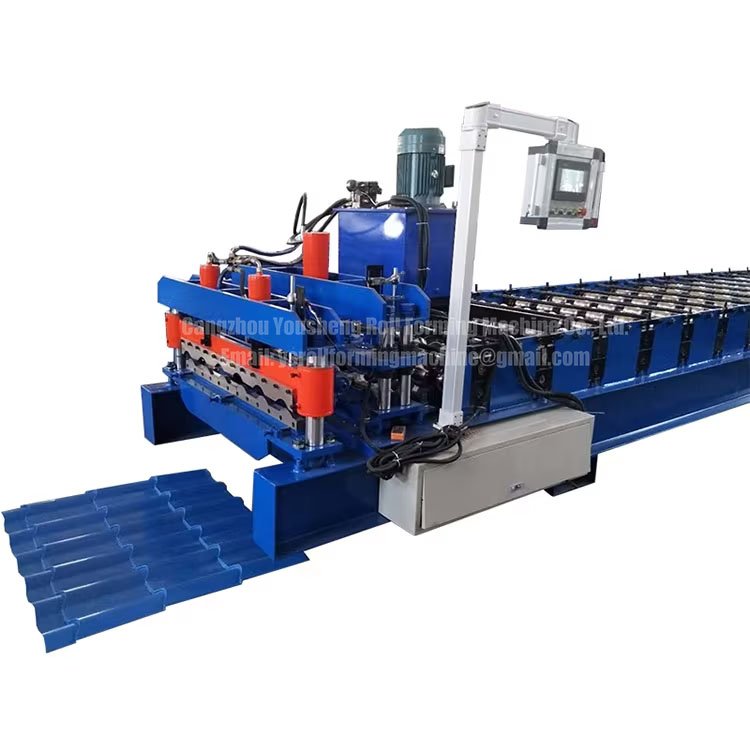

| Size: | About 6.5m*1.5m*1.5m |

|---|---|

| Power: | 5.5KW |

| Voltage: | 380/220v 50hz 3P/According to client needs |

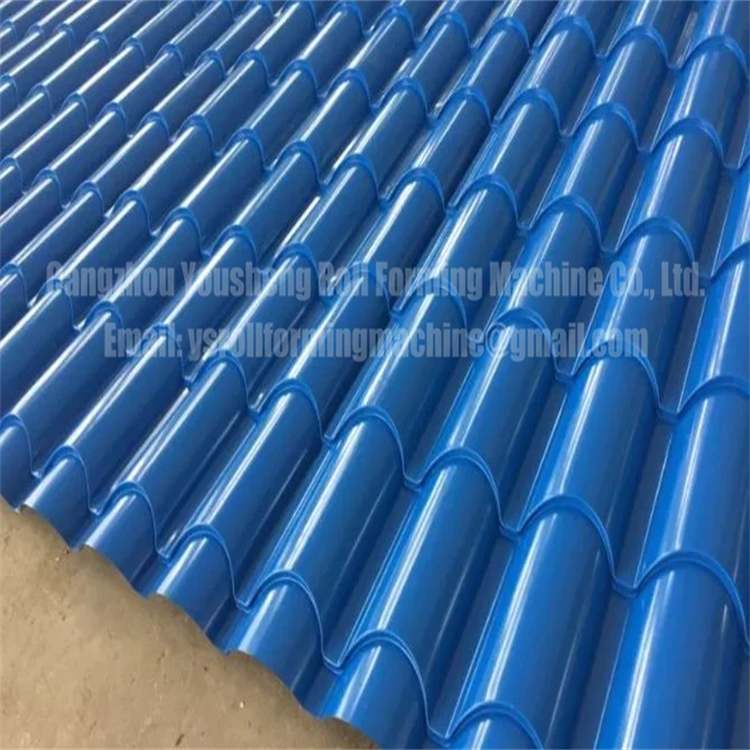

| Raw material: | GI/PPGI/Q235/Q345 |

| Raw material length: | Any length |

| Output: | 4m/min |

| Thickness: | 0.3-0.9mm |

| Type: | PLC |

Glazed Tile Roll Forming Machine

The high-speed glazed tile forming machine is a special equipment for continuous rolling and cold forming of steel plates. Coiled steel plates are used as raw materials, uncoiled, continuous rolled, cold formed, and automatically hydraulically cut into finished plates. The PLC screen sets the quantity and length of finished boards, which can realize automatic production.

Hot selling glazed tile machine

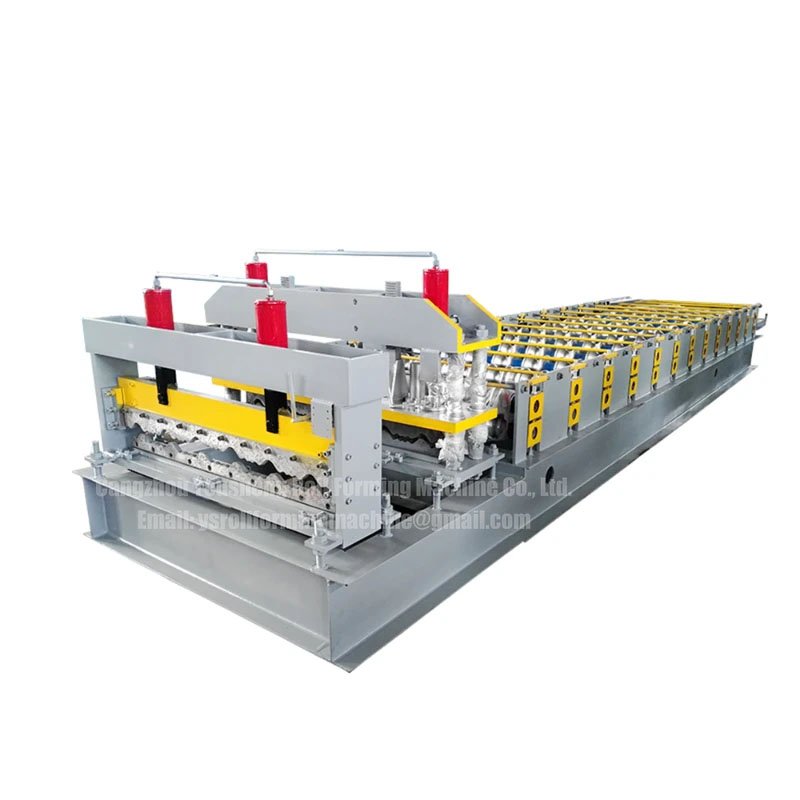

Pump station capacity: 50L

Uncoiler: manual/hydraulic

Shearing method: hydraulic shearing

Operation screen: portable

Motor: Siemens/other brands

Method: automatic forming roller pressing

PLC brand: Delta/Mitsubishi

Advantages: save floor space

Certification: ISO/CE

Shaft diameter: solid shaft 70mm

Version style: customizable

Transmission mode: chain/gearbox

Feeding width: 1000mm/1250mm

Material thickness: 0.3-0.8mm

Cut length: any length