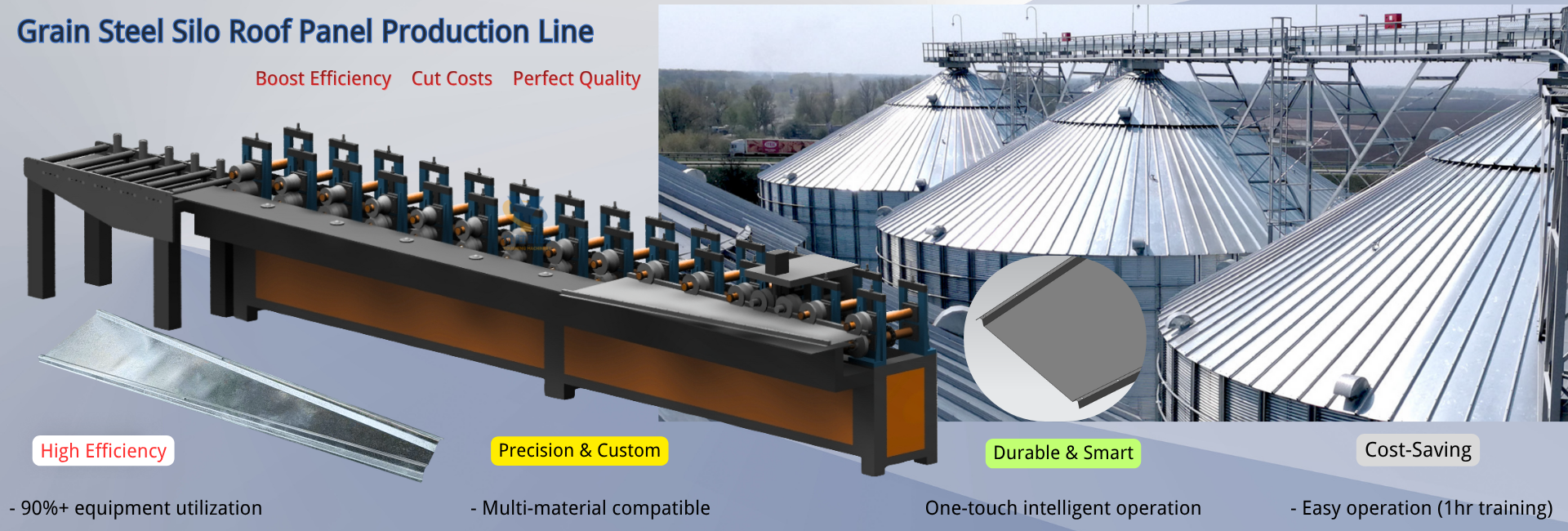

High-Performance Silo Roof Panel Roll Forming Machine--Detailed interpretation

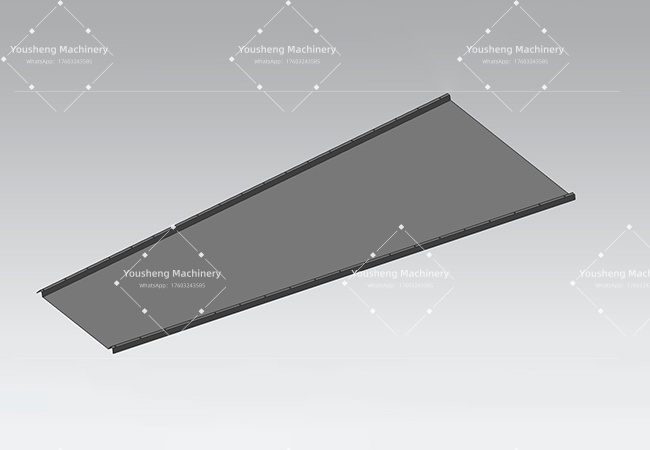

Our silo roof panel production line can continuously complete rolling and punching work, ensuring accuracy while increasing production. This is a curved metal sheet specifically used to cover and close the roofs of various industrial silos, such as grain silos, cement silos, feed silos, and liquid storage tanks such as water tanks, oil tanks, and rainwater tanks. We use automation to reduce labor costs and ensure that your silo roof panel profile is delivered quickly, bringing efficient transformation to your industry.

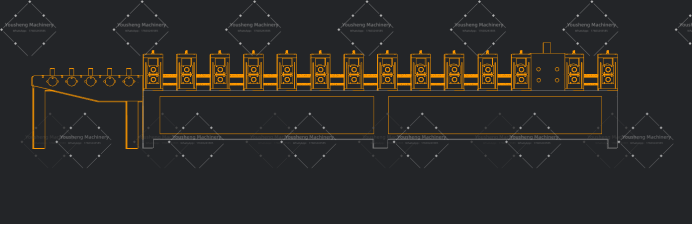

Layout diagram (for reference only)

Why Choose Our Silo Roof Roll Former?

Versatile Plate Processing:

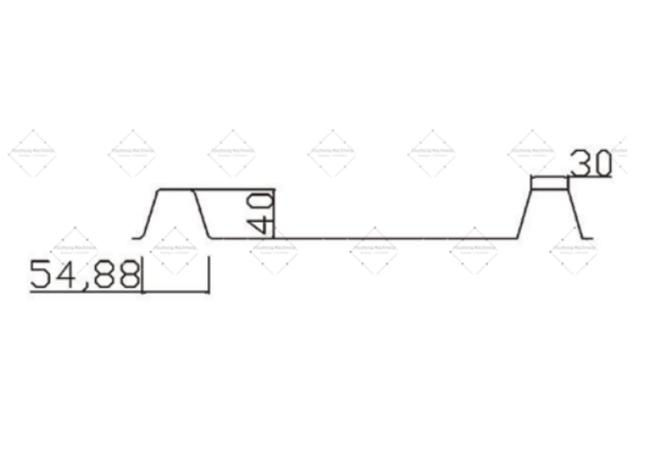

The machine can process plates of varying widths and thicknesses.

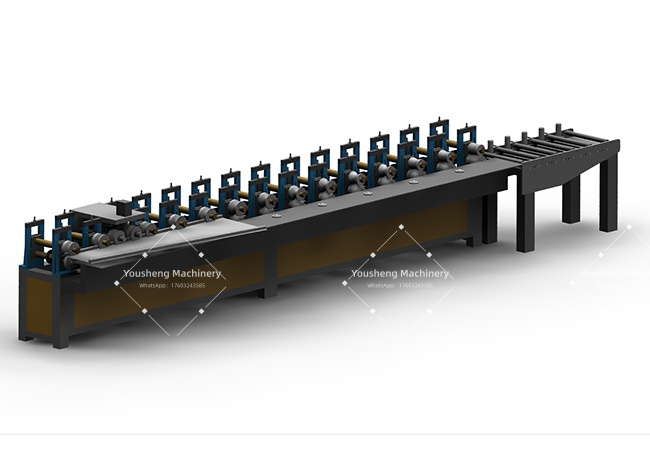

Sturdy and Durable Frame Structure:

The gantry-style structure ensures stable operation over extended periods of time.

Uncompromising Accuracy:

Our PLC program and servo motor design ensure zero-tolerance profile accuracy.

Easy Operation and Maintenance:

The user-friendly electronic control system allows for easy setting of plate length and quantity. Simple maintenance procedures reduce maintenance costs.

Technical Specifications:

| Parameter | Specification |

| Material | Galvanized steel, Stainless steel, Color coated steel coil, Aluminum-zinc-magnesium alloy steel coil |

| Coil Thickness Range | 0.8 mm – 2.5mm |

| Coil Width | 300-800mm (customizable) |

| Forming Speed | 8-10m/min (adjustable) |

| Roller Material | GCr15 steel with hard chrome coating |

| Number of Roll Stations | 11-14 stations (depending on profile) |

| Main Motor Power | 5.5 kw |

| Cutting System | Hydraulic post-cutting, blade material: Cr12Mov |

| Control System | PLC + HMI touchscreen |

| Drive System | Chain or Gearbox drive(customizable) |

| Punching | Optional/(customizable) |

| Power Requirement: | 380V / 50Hz or customized according to customer’s local standards |

What can our equipment bring to you?

- Strict Quality Control: From raw materials to finished products, we rigorously control the precision of every silo roof profile.

- Cost Reduction: We eliminate third-party intermediaries who earn unnecessary fees.

- Gaining Customer Trust: With our own production team, we dispel customer doubts and win them over.

What are our strengths?

One-stop solutions:

We offer not just a single machine, but a complete line of large-scale silo production lines, including silo wall panel forming machines, silo stiffener roll forming machines, and silo roof sheet forming machines.

Customized services:

We design a production line tailored to your specific needs and company’s development.

Patient service and technical support:

We provide comprehensive technical guidance, including machine operating manuals and video tutorials.

Customer reviews:

We provide production solutions for large-scale agricultural grain storage, liquid storage tank, and building materials engineering clients worldwide, with over 100 successful cases and extensive production experience.

The cost of silo roof panel roll forming equipment depends on the level of automation, customization, and configuration. For an accurate price quote, please contact us and tell us your specific needs. We will provide you with an accurate and competitive price.

Absolutely. We provide comprehensive pre-sales operation training and full-service after-sales support, including technical support and spare parts supply, to ensure your equipment runs smoothly for years to come.

Yes, we are experts in customized silo roof panel roll forming machines, designing equipment tailored to your precise profiles and specifications.

We can provide add-on design to your machine according to your needs, turning it into brand new equipment.