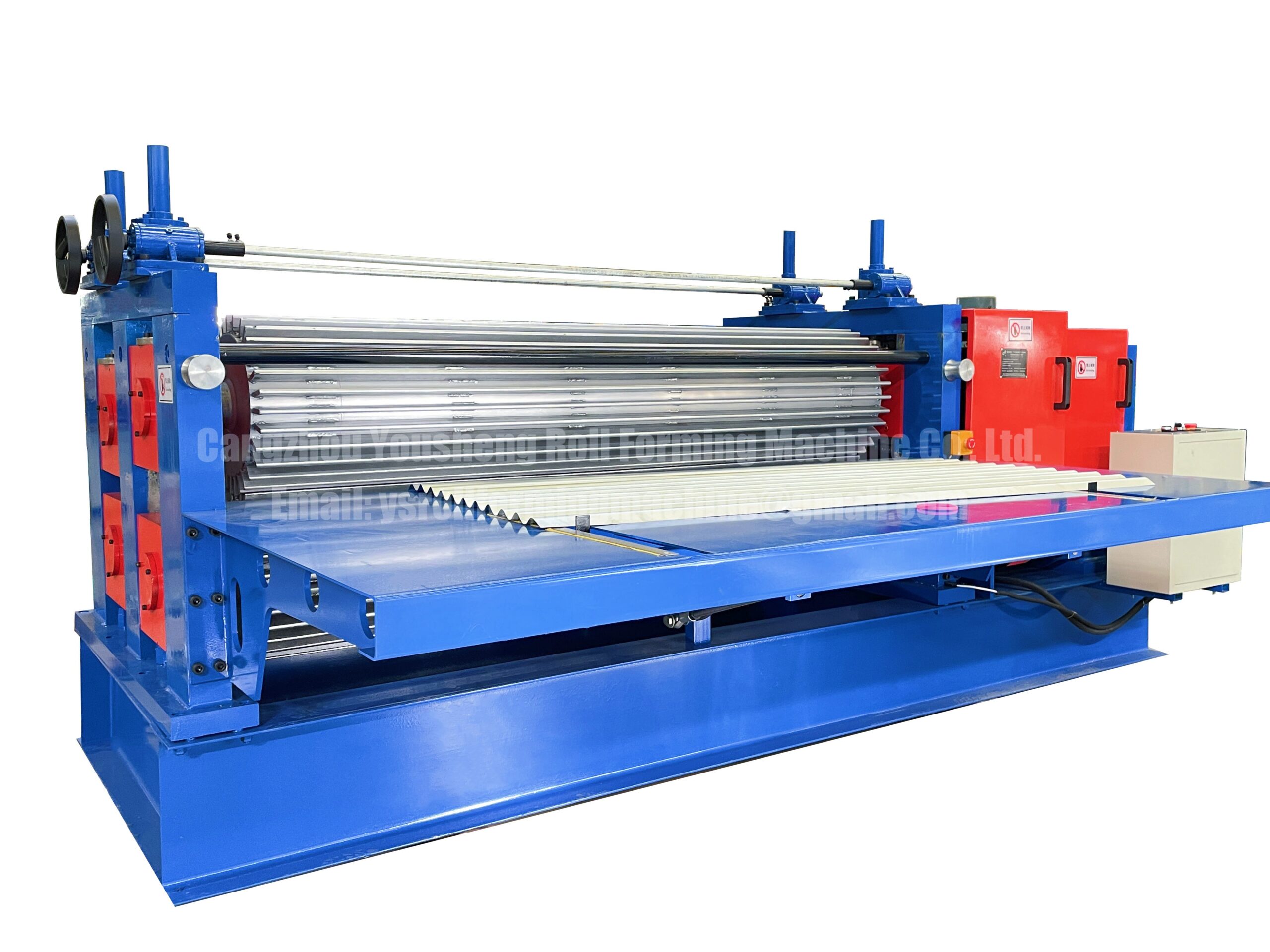

Barrel Corrugated Roofing Sheet Machine

Barrel Corrugated Sheet Machine – Product Introduction

Our barrel corrugated sheet machine is designed for roll forming high-strength thin sheeting. Utilizing our engineers’ unique design philosophy, this machine achieves high-speed, efficient sheet processing with guaranteed sheet quality.

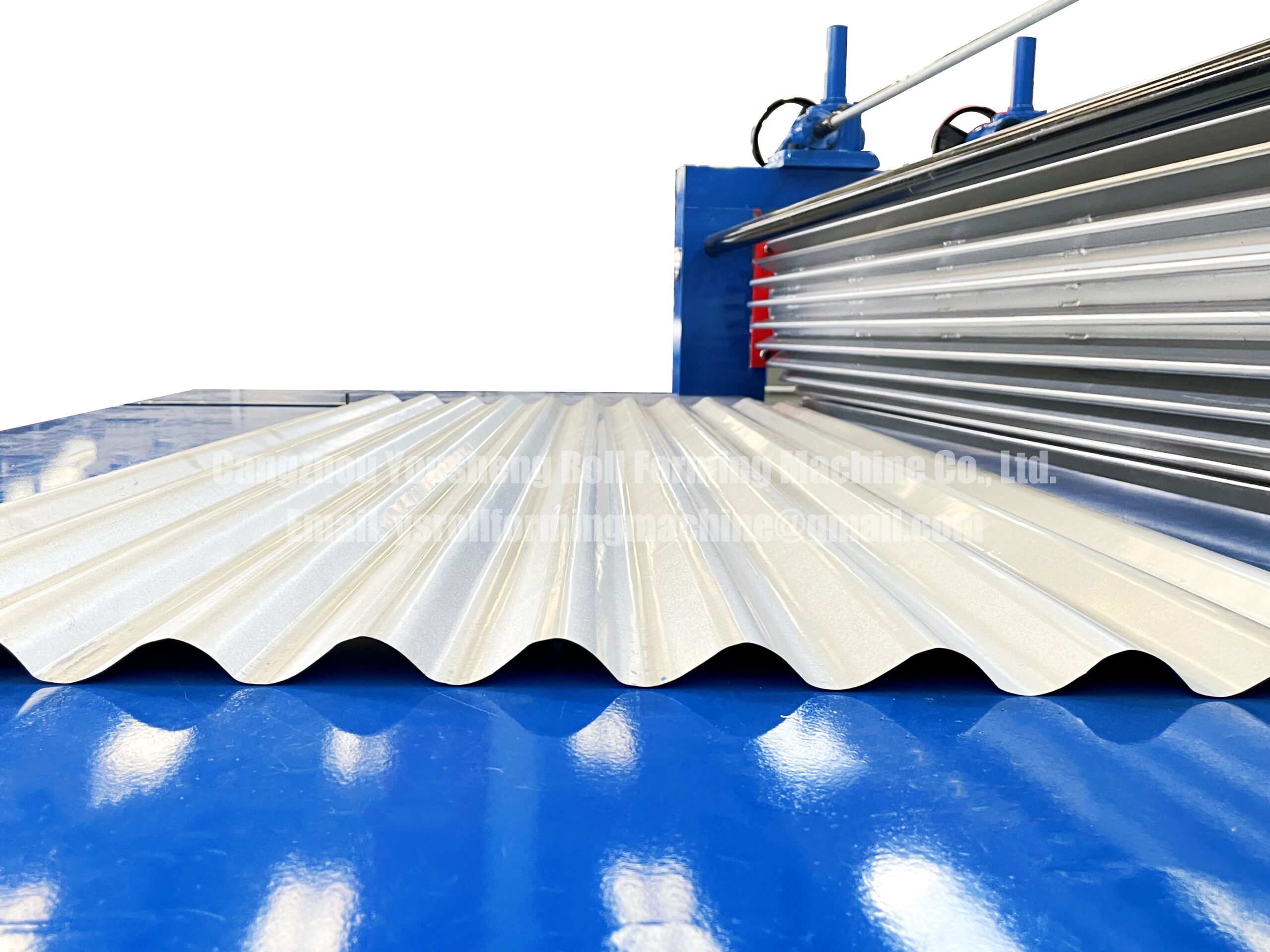

This profiled sheeting is suitable for roofing, wall cladding, and interior and exterior wall decoration in industrial and residential buildings, warehouses, specialty buildings, and large-span steel structures.

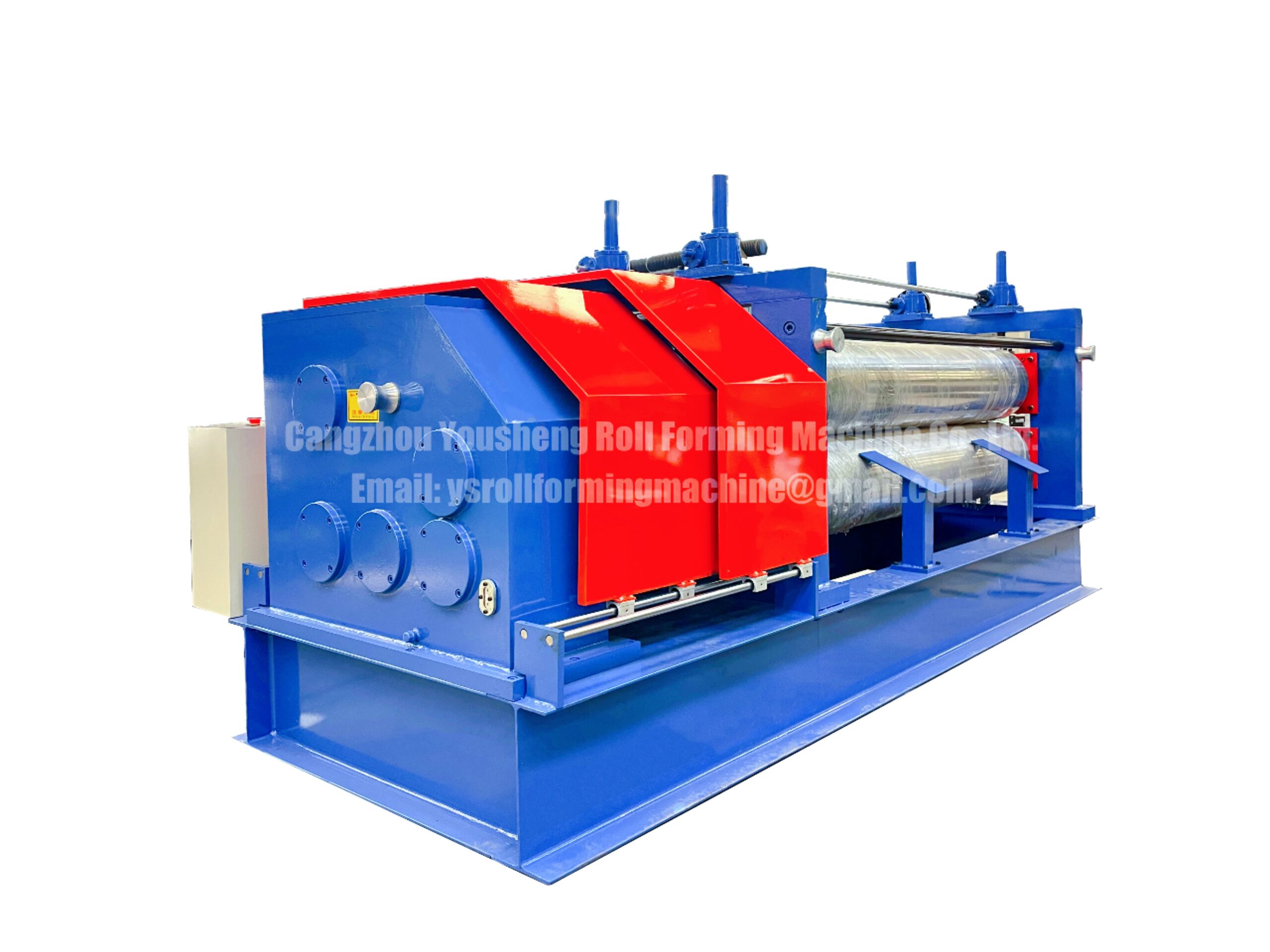

Barrel Drum Type Corrugated Machine

Our barrel corrugated machine is easy to operate and can process corrugated sheets with perfect curvature, helping you achieve efficient production and dominate the market.

Machines designed specifically for processing high-strength thin plates.

Key Features:

Designed for High-Strength Sheet Materials:

This roller-type corrugator is specifically designed to produce G550 high-strength sheet materials, revolutionizing traditional cold roll-forming methods.

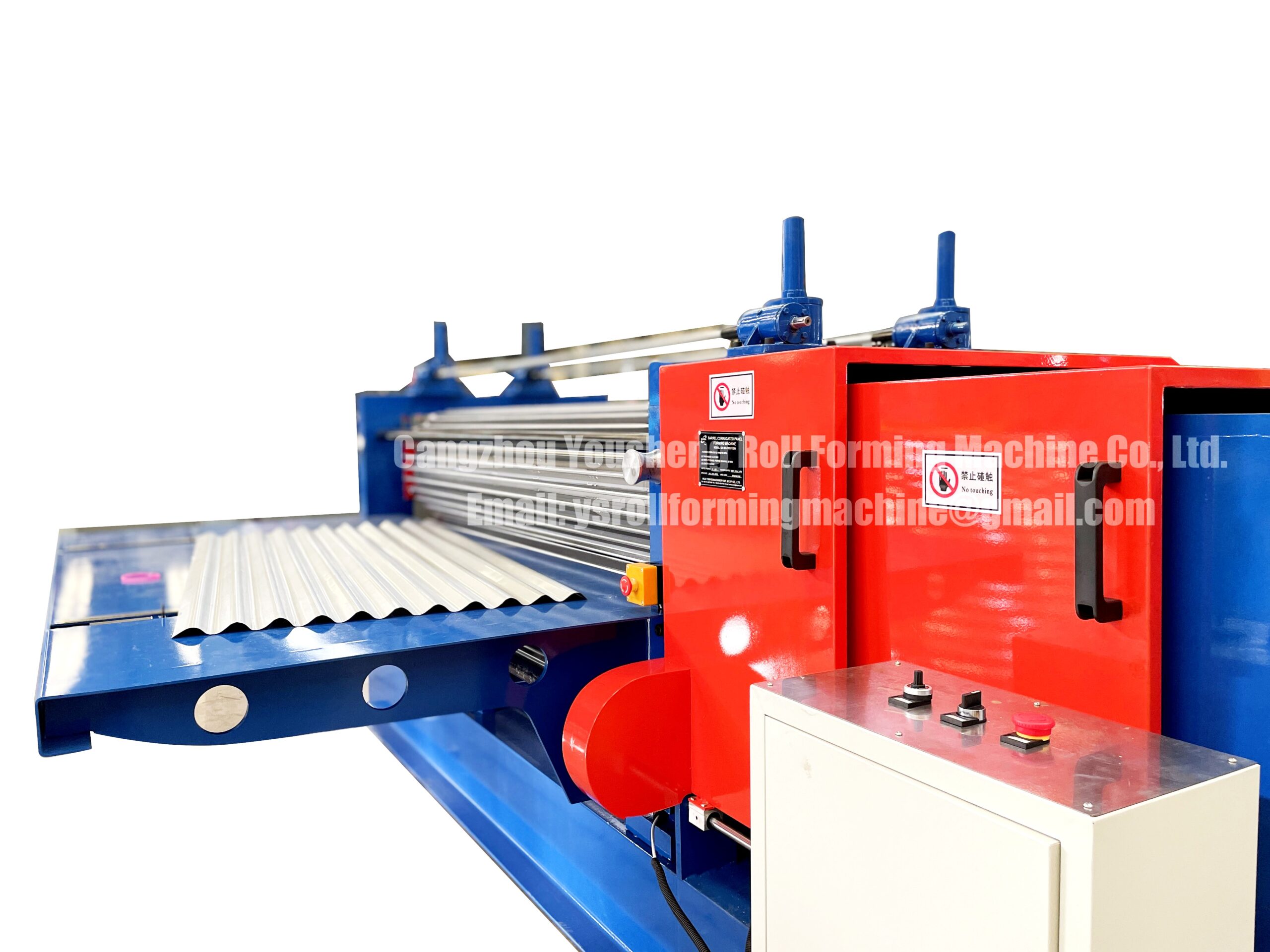

Easy to Operate:

Our machine is equipped with a simple, easy-to-understand PLC control program, making it easy for even novice operators to operate.

Highly Efficient Production:

The machine can produce stacked sheets, capable of rolling up to four sheets at once, at double the production speed.

| Parameter | Specification |

| Suitable Material | Galvanized steel (G550) |

| Sheet Thickness Range | 0.1 mm – 0.5 mm |

| Sheet Lengh | 2.5m/3.0m/4.0m/4.5m/5m (customizable) |

| Roll Revolution | Max 12/minute (adjustable) |

| Roller Material | GCr15 steel with hard chrome coating |

| Control System | PLC |

| Drive | Geared motor 7.5Kw with reducer |

| Power Supply | 380V/50Hz/3Ph (customizable) |

| Tile Type | Corrugated |

| Dimension (L×W×H) | Approx. 6.5m × 2.5m × 1.5m (depends on configuration) |

Where is corrugated sheet used?

Residential Buildings: Light Steel Buildings/Portable Buildings

Public Facilities: Parking Lots/Portable Restrooms/School Sports Facilities

Industrial Buildings: Factories/Production Workshops/Logistics and Freight Transfer Stations

Agricultural Buildings: Cattle Barns/Stables/Poultry Farms

Gambian customer feedback video

On the right is a feedback video from our customer in Gambia, West Africa, showing their use of the machine. The customer is using our 2.6-meter-long machine, which can process both G550 and PPGI materials, significantly contributing to their production efficiency.

Why use our barrel corrugation machine?

1. Our corrugation machine is designed for producing high-strength thin sheet, suitable for rolling 0.1-0.5mm galvanized sheet.

2. We deliver ex-factory and strictly control machine quality. You can see both semi-finished and finished barrel corrugation machines at our company.

3. We have a systematic management team consisting of: Sales Department, Design Department, Production Department, Quality Inspection Department, After-sales Service Department, and Overseas Commissioning Department.

If necessary, we can arrange for an engineer to visit your factory for installation, commissioning, and production support, as well as provide guidance on how to use the machine.

Yes, we can provide custom designs to meet your specific corrugated sheet dimensions.

Before your machine is shipped, you can visit our factory for a hands-on training session.

After your machine is sold, we provide 24/7 online guidance to help you achieve rapid production.

After the machine is sold, we provide a one-year warranty and lifetime technical support.