Innovative Design CZ Purlin Roll Forming Machine

Innovatively designed fully automatic electric CZ Purlin machine to create speeds up to 30m/min

30 seconds super fast model replacement, one-click model replacement through intelligent program computer, saving personnel operation time and efficient conversion

Equipped with high-end motor brand, long-term high-power output production, Unmole Shearing can complete the conversion of multiple specifications, and the productivity increases dramatically

Innovatively Designed CZ Purlin Roll Forming Machine

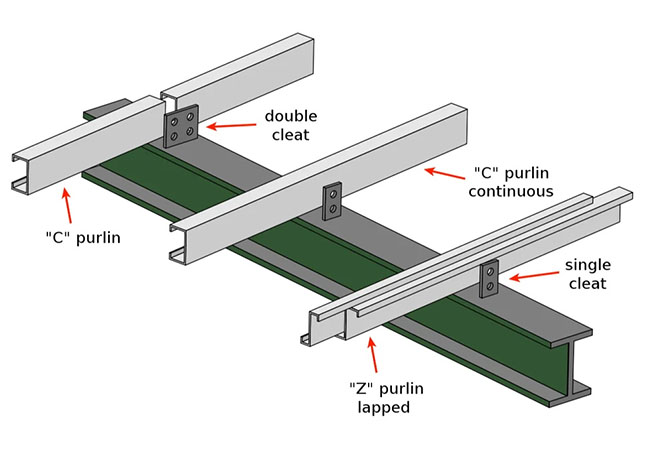

Purlin profiles are important structural components in the building materials industry. They are used in the construction of steel structure workshops and can be used together with roof panels to build a practical workshop.

This production line can produce both C-shaped purlins and Z-shaped purlins, achieving dual purposes in one machine and greatly improving the production efficiency of purlin profiles.

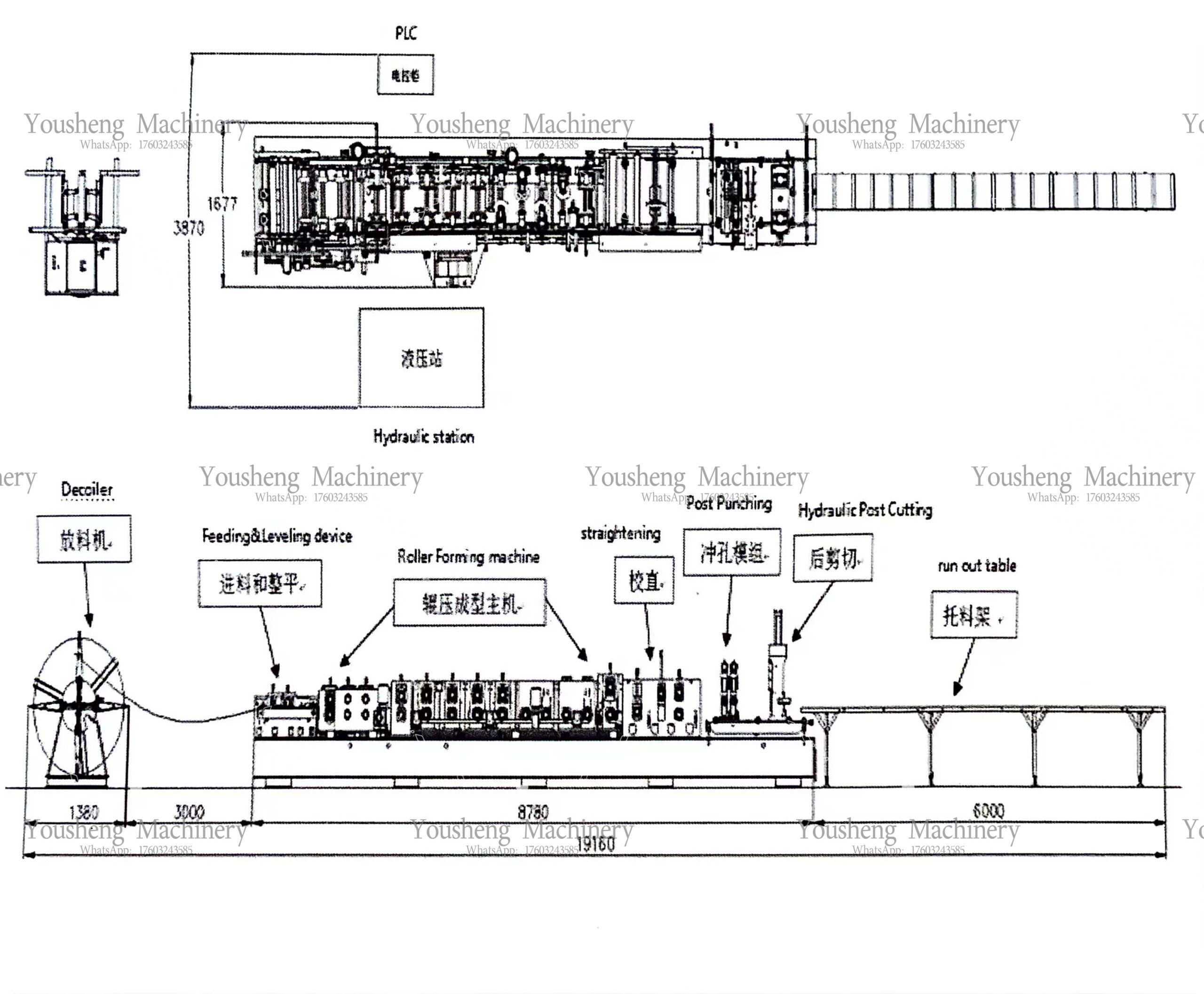

It consists of an uncoiler, a roll forming machine, a replaceable punching unit, an infinite cutting device and a material receiving platform. One person can complete the production, reducing labor costs.

What parts does the machine contain?–Machine flow chart

Layout Diagram:

Core Technical Features – How We Become Your First Choice for Purlin Roll Forming Machines?

Designed for High Precision and Performance

PLC Control System: Ergonomic intelligent PLC control system, simple to set production parameters

Quick Changeover: Quickly change between C- and Z-shaped purlins in 10 minutes, eliminating the need for time-consuming changes

Precision Stepless Shearing: Our stepless shearing method ensures burr-free purlin profiles and error-free installation

Automatic Splicing Device Compatible: We can customize fully automatic splicing and palletizing functions, truly enabling one-person production and optimizing your costs.

Technical Specifications:

| Parameter | Specification |

| Material | Q195/Q235 hot-rolled strip steel/ hot-rolled galvanized strip steel /Q355 |

| Coil Thickness Range | 1.0 mm – 3.0 mm |

| Coil Width | 400mm (customizable) |

| Forming Speed | 30 m/min (adjustable) |

| Size adjustment method: | Electric/PLC computer |

| Roller Material | GCr15 steel with hard chrome coating |

| Number of Roll Stations | 18 stations (depending on profile) |

| Main Motor Power | About 22kw (based on profile and thickness) |

| Cutting System | Hydraulic post-cutting, blade material: Cr12Mov |

| Control System | Delta PLC + touchscreen |

| Drive System | Chain drive |

| Decoiler | Manual or hydraulic, 5–10 tons |

| Power Supply | 260v/380V/50Hz/3Ph (customizable) |

| Dimension (L×W×H) | Approx. 10m * 1.0 m*1.5m

(depends on configuration) |

- Can this machine really handle urgent and high-volume orders?

- The C- and Z-type rollers are integrated into one machine, reducing the footprint of two machines.

- The quick interchangeability doubles order processing efficiency, allowing ample time to produce ready-to-use purlin profiles.

- You can earn back the machine’s cost in approximately 18 months.

- The machine has a production speed of 30 meters per minute. Based on a standard thickness of 2.5mm, the machine can produce 100 tons of purlin profiles in 8 hours of non-stop operation.

Would you like to try swapping C- and Z-type purlins in 10 seconds?

We’ve previously shared our manual purlin changeover method, and it’s been very well received.

We customized a purlin forming machine with a 10-second quick changeover based on the needs of an Australian customer. Their requirement was to use a PLC program to input dimensions on an LCD touchscreen for changeover, so we developed a fully automatic purlin forming machine to meet their needs.

How to manually swap between C-type and Z-type?

If your CZ purlin machine requires manual replacement of the C- and Z-shaped purlins, how do you do it?

Watch the video on the left. It will teach you how.

we can only takes 50 seconds to swap between C- and Z-shaped purlins.

Why choose our automatic CZ purlin forming machine?

For our clients, whether they are large structural steel manufacturers or traders, the productivity and versatility of our forming machines are crucial.

If you’re worried about a single machine only producing a single profile or experiencing inconsistent production efficiency, don’t worry! Our fully automatic CZ purlin forming machine is designed to eliminate production bottlenecks.

It integrates the production of C and Z purlins into a single platform, enabling quick switching between C and Z purlins. Say goodbye to the days of single-machine production. This powerful production system will keep your company ahead of the competition.

What do our customers say?

Real feedback from a Fijian customer:

“We purchased Yousheng’s intelligent CZ integrated purlin forming machine last year. Our company’s output value has increased from 10% to 35%. The CZ purlin’s rapid changeover has increased our production efficiency by 60% and reduced our labor costs. Previously, it took at least two people to complete the raw material installation. Now, with the hydraulic uncoiler, one person can do the work of two workers, allowing us to receive larger production orders.”

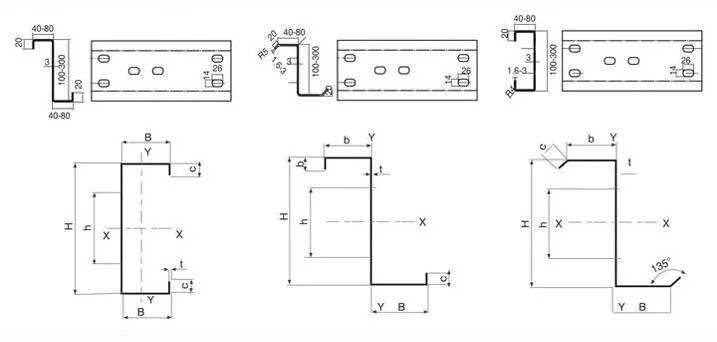

Yes, we design C- and Z-shaped purlins according to your needs. We can process various sizes and punching dimensions.

Generally, the machine is completed within 50 days. The detailed delivery time depends on your order.

If you need an engineer to come to your factory to debug the equipment, we will dispatch experienced engineers.

We can provide a design and retrofit solution for your old machine to help you increase your production value.

Two. types. One is to use an electric button, and the other is to use a PLC computer.