Roof Sheet Roll Forming Machine

Metal Roofing Machine–Product Introduction

Roofing panels are widely used in the global building materials industry. As a manufacturer of roofing panel forming machines, we are dedicated to meeting customer needs, improving machine productivity, and conserving energy. We offer one-stop services, from single machines to entire production lines.

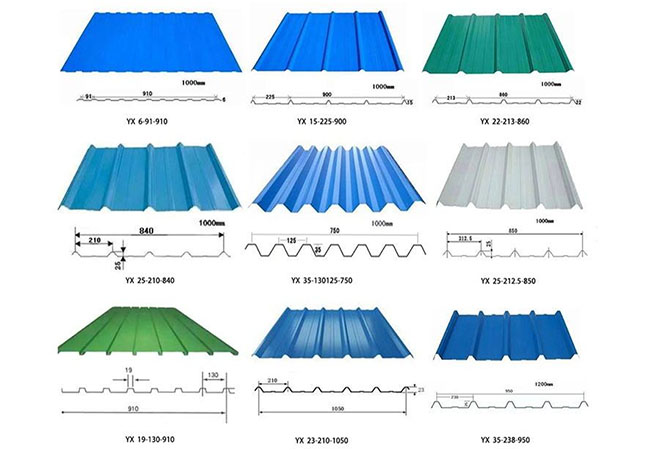

Roof panel machines can produce common trapezoidal, corrugated and glazed tile shaped sheets, and also involve ridge tile sheets, the common materials are galvanized steel coils, stainless steel coils, aluminum coils.

Roofing Sheet Roll Forming Machine

From the paper-like galvanized coil to the final, ready-to-install sheet, this forming machine includes an unwinder, a roll former, and a splicer. This allows one person to easily and efficiently complete sheet production.

Machine Flowchart:

Main performance:

Easy to operate

Low-cost maintenance

Applicable materials: color chart rolls, stainless steel

Customizable with your company logo

Product Application

Steel structure factory buildings

Used for roof and wall panels in large-scale manufacturing workshops

Warehouse and logistics factory buildings

Suitable for the construction of large-scale warehouse and logistics centers

Mobile prefabricated houses

Construction of mobile residential homes

Light steel villas

Used for the decoration of light steel villas for home or office use

Technical Specifications

| Parameter | Specification |

| Material | PPGI & GI & Stainless steel |

| Coil Thickness Range | 0.3-0.8 mm |

| Coil Width | 914mm/1000 mm / 1200mm/1250 mm (customizable) |

| Forming Speed | 8–20 m/min (adjustable) |

| Roller Material | GCr15 steel with hard chrome coating |

| Number of Roll Stations | 10-12 stations (depending on profile) |

| Main Motor Power | 7.5 kW (based on profile and thickness) |

| Cutting System | Hydraulic post-cutting, blade material: Cr12Mov |

| Control System | Siemens PLC + touchscreen |

| Drive System | Chain or Gearbox drive |

| Decoiler | Manual / Hydraulic |

| Power Supply | 380V/260V/50Hz/3Ph (customizable) |

| Dimension (L×W×H) | Approx. 10m × 1.3m × 1.5m (depends on configuration) |

- What Can We Do? (Our Services)

Pre-sales Training: Customers can arrange for one or two people to come to our factory to learn about the machine, including how to load the uncoiler, how to operate the main roller unit, and PLC electronic control.

On-site Installation: We provide vido guidance with the customer on how to install the machine to ensure accurate installation.

Customization: We consider the individual needs of each customer and can customize the machine to suit their needs.

After-sales Service: Our team provides 24/7 service, with no time difference, to assist engineers in resolving any issues arising from machine operation.

Why use double-layer roof sheet forming machine?

We have an Omani customer who bought our single-layer roof panel machine six years ago. Our machine helped him complete a number of government building materials projects.

After he made a high profit, he began to investigate the roof tile market and found that glazed tile sheets were more beautiful than trapezoidal roof panels when used on the roof of the house. He began to ask us for information about glazed tiles.

After research, he also wanted to expand the scale of production and wanted to process the shape of corrugated panels. However, due to the limited space in his current factory, he could not place another machine. With our recommendation, the double-layer roof panel machine can solve this problem.

It can process two different shapes of roof panels in the space of one machine, thus solving the customer’s space problem while expanding the processing of corrugated panels.

Yes, we have an overseas service team that can visit your factory to provide guidance. Once the machine arrives at your factory, we can also have a video call with your salesperson to clearly understand the machine’s condition and provide quick installation guidance.

We offer a one-year warranty and lifetime guidance.

Yes, we serve a diverse customer base and can customize it based on your budget, usage scenario, and region of operation.