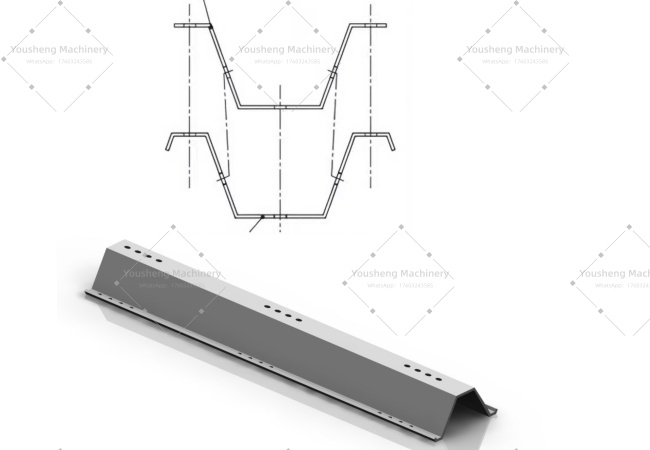

Silo Stiffener Roll Forming Machine - Product Introduction

Large grain steel silos are composed of Grain Silo sheet, silo stiffener sheet, and silo roof panels. Silo stiffener sheet are an essential component in the manufacture of large silos. A strong silo relies on these stiffener profile for robust support.

Our silo stiffener forming machine can continuously process large quantities of profiles. It uses solid materials and produces precise forming precision, ensuring a perfect connection with the silo corrugated sheeting.

Why choose our silo stiffener machine?

- One-step Forming Process

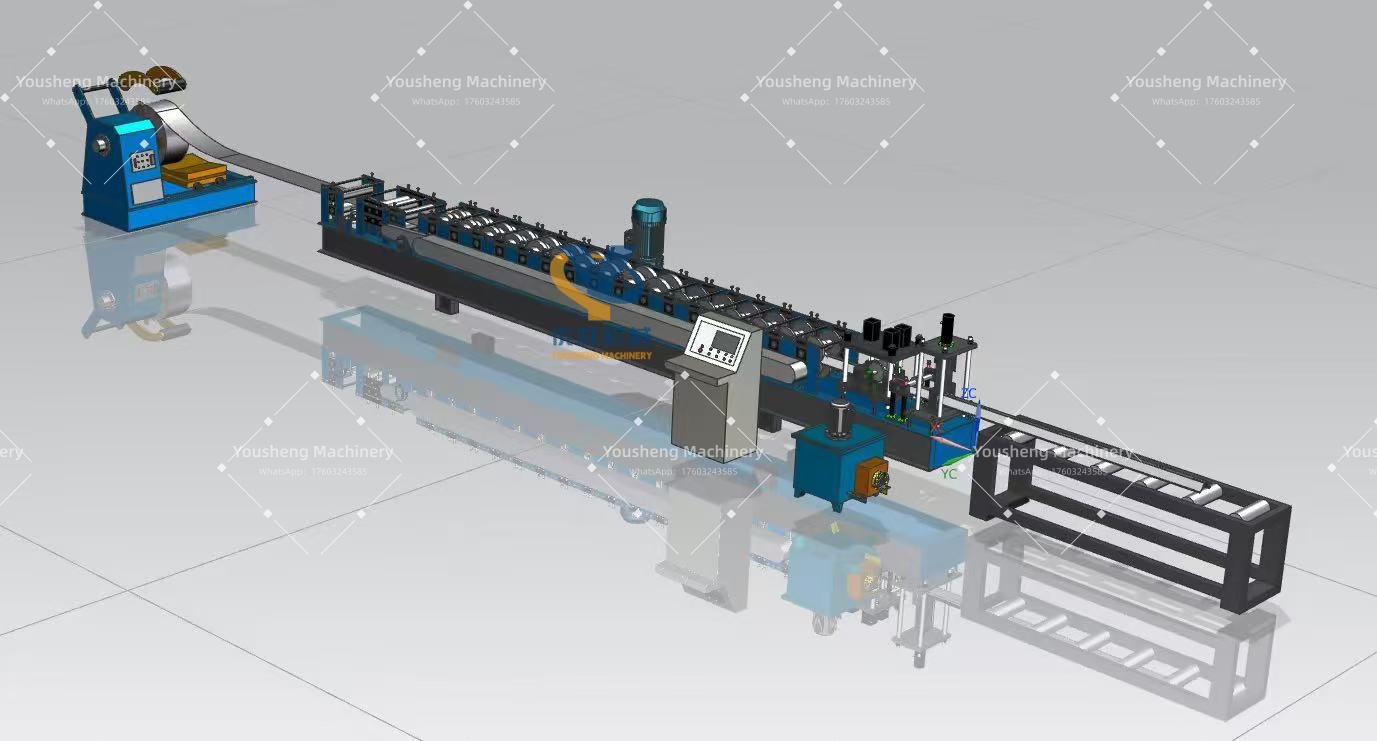

From galvanized steel coil to finished reinforcement profile, our machine completes the process in one go, eliminating the need for additional steps. Its production efficiency is 5 to 10 times higher than traditional processes.

- Cost Savings

Our machine requires only two people to load the material and one person to oversee production.

- Multi-Specification Processing

The machine can process profiles of varying thicknesses to meet custom requirements, adjusting the roller thickness in just one minute.

- Easy-to-Operate PLC Control System

The machine is equipped with an advanced and easy-to-use control system, allowing workers to supervise production after basic training.

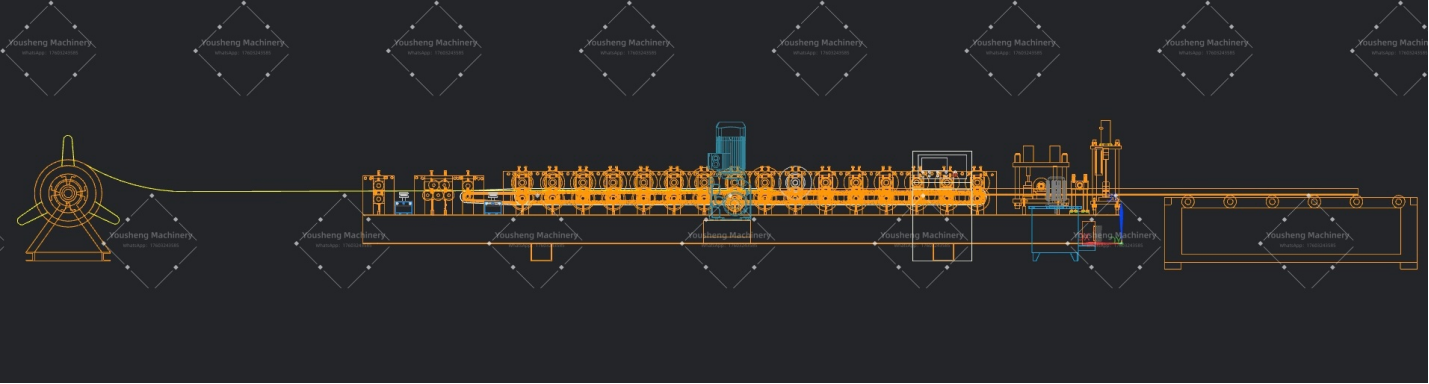

The production line consists of uncoiler, leveling, roll forming, punching, cutting and stacker, which improves production efficiency and saves labor.

Technical parameters and specifications

| Material | Galvanized/Carbon steel |

| Meterial Thickness | 2-6mm(millimeter) |

| Number of rows | 18-22 rows(depending on profile) |

| Coil Width | 300-380mm(customize) |

| Hole Size | 12*14mm / Φ12mm(customize) |

| Motor Power | 18-22kw (depending on profile) |

| Roller Material | Cr12MOV |

| Electronic Control System | Brand PLC+ Human-machine interface |

| Forming Speed | 8-12m/min |

| Cutting Length | 3m(Any length) |

| Drive System | Chain or Gearbox drive |

| Power Supply | 260V/380V/50Hz/3Ph (customizable) |

Application areas:

Grain storage field: Grain Storage Silo/Hopper Bottom Silo/Flat Bottom Silo

Water treatment field: Galvalume water storage tank/Liquid storage

Chemical industry in building materials field: Cement tanks/Fly ash tanks

Real Case Study

In 2024, we delivered an automated silo stiffener production line to a Turkish customer. Previously, the customer used CNC bending machines and laser cutting machines to produce stiffener profiles, which was time-consuming, labor-intensive, and inefficient. After we provided the machine, it now operates at a speed of 8-10 meters per minute, requiring only one person to complete the process. This increased efficiency by 50%, freeing the customer from the hassle of silo stiffener processing.

We specialize in designing silo production lines. If you’re still struggling with low production efficiency and inaccurate product quality, don’t hesitate to contact us for the best solution.

Our machine is semi-automated, requiring only one person to supervise loading and unloading the material.

Yes. If necessary, we can arrange for an engineer to visit your factory to assist with machine installation and commissioning.

Yes. We can provide a layout design based on your factory space, allowing you to efficiently utilize your space.

Depending on the configuration of each machine, we include a certain number of wearing parts (such as punches, oil pipes, etc.) with the machine to facilitate quick replacement in the event of damage.

You can set the sheet material to any length using the PLC control box; this is not a fixed setting.