Solar Photovoltaic Bracket Roll Forming Machine

Solar photovoltaic bracket profiles play a decisive role in the energy industry. Similarly, as a manufacturer of photovoltaic brackets machie, we can meet various needs of customers in the industry. Photovoltaic brackets are divided into ordinary brackets and anti-seismic brackets, both of which are used as brackets. The structure of the whole production line is more complicated, and the precision required for the profiles is higher.

Solar Photovoltaic Bracket Roll Forming Machine

Yousheng Machinery specializes in the production of photovoltaic support bracket machine.We are able to provide solutions for photovoltaic support molding machines for facility construction in the solar industry.

We are a professional manufacturer dedicated to cold bending equipment, our engineers can customize different equipment according to the needs of different customers.

It is a full automatic line to produce the solar photovoltaic bracket strut ,which is a special bracket designed for placing, installing and fixing solar panels in solar photovoltaic power generation system.

It is suitable to produce strut channels with thickness from 1.5-2.5mm, even up to 3mm.

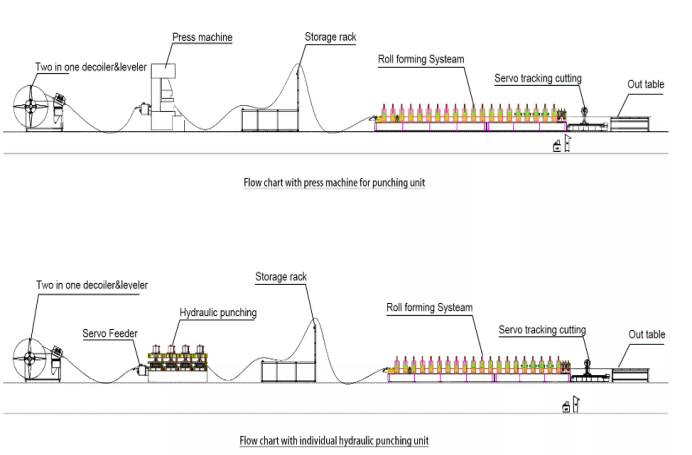

Photovoltaic bracket production line configuration components

This line consists of hydraulic uncoiler, servo feeder, press machine/ individual punch unit for punching hole, roll former, servo tracking cutter, and electrical & hydraulic system.

Machine Specifications

| Applicable Industries: | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works , Other |

| Feeding material: | Galvanized / Stainless Steel / Carbon Steel |

| Thickness of the plate: | 1.5-3.0mm |

| Diameter of the axle : | 90mm |

| Rolling stages: | 18 |

| Productivity: | 10m/min |

| Cutting blade: | Cr 12 Mov |

| Roller material: | Cr 12 |

| Voltage: | 380V 50Hz 3phase or as requirement |

| Transfer method: | Gearbox |

| Weight: | 7500kg |

| PLC | DETLA |

| Total power: | 22kw |

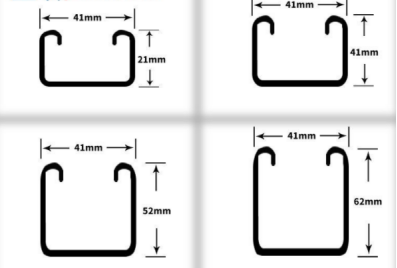

Profile drawing

Profile display

Frequently asked questions

Q: 1. How to solve the problem that the roller sticks to the zinc layer of the raw material during the rolling process of the machine?

During the production process of the machine, the roller has been in the state of rolling, so that the zinc layer on the surface of the galvanized sheet will fall off. The customer will use it for a long time to cause the roller to be uneven, the size and gap of the roller to be inaccurate, etc., so we have the following solutions. Program

A: We can add an oiling device, also known as an automatic oiler, to the feeding port of the machine. There is felt on the automatic oiler. After dripping oil, there is a thin layer of oil on the surface of the steel plate, so that the Avoid the phenomenon of falling off or very little phenomenon.

Solar Panel Roll Forming Machine

Cutting: Servo Cutting